The Very Effective Hydrogen Carrier: Hydrocarbon

Advanced Renewable

Tue , 14 May 2024 11:41 WIB

After we can produce biohydrogen effectively from biomass or charcoal, the next challenge is how to store and transport this biohydrogen when needed at a different time or place from the time/place of production.

Of the many that we studied, including storing in ammonia, in magnesium, in oxygenates, in natural charcoal and in hydrocarbons, those we recommend most are the last two. Charcoal is still the most recommended if hydrogen will be produced and used in the same place.

However, if hydrogen is to be produced and used in another place or time, where storage and transportation is required, then storing hydrogen in the form of hydrocarbons is the most effective. The graph below explains the effectiveness of hydrocarbons as hydrogen carriers.

All hydrocarbons of any C chain length can be used as hydrogen carriers, but their performance decreases with the longer the C chain. The total hydrogen that can be delivered by hydrocarbons is also very high, the range is 43% to 50% of the weight of the hydrocarbon used as the carrier.

This high hydrogen delivery is because when we use hydrocarbon as a carrier, hydrocarbon will deliver hydrogen from 3 sources. The first is hydrogen carried by the hydrocarbon molecule itself, the range is 15% to 25% of the weight of the carrier. The second is hydrogen from steam used for the reforming process, and the third is from steam used for water gas shift, where from these last two sources there is an additional approximately 13% - 14% each of the weight of the hydrocarbon used as the carrier.

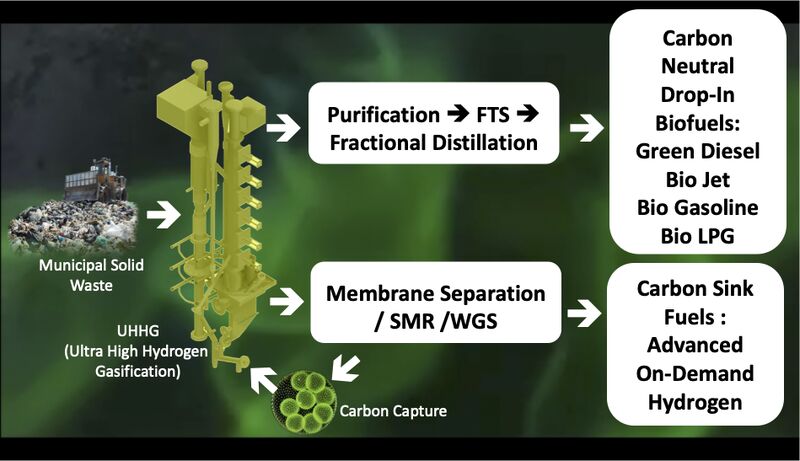

The reactor that we use to model hydrogen storage in hydrocarbons and reform it back into hydrogen when it is needed is a reactor that we call the Synthesis and Reforming Reversible Reactor (SR3) as in the picture below.

The hydrogen input that can be stored in hydrocarbons can be pure hydrogen, but what is more economical is syngas with an H2/CO>2 ratio. Because even if you want to store pure hydrogen, you also need CO gas as a reactant to make it a hydrocarbon.

Because syngas can easily be produced from biomass or charcoal, the hydrogen and hydrocarbons processed by SR3 are categorized as biohydrogen and biohydrocarbon. From the graph below, we will also be able to calculate a reasonable price for this biohydrogen, it will be very competitive because it only takes 2 to 2.3 kg of biohydrocarbon (bioLPG, biogasoline or greendiesel) to produce 1 kg of biohydrogen whose energy density is 2.7 times the energy density of hydrocarbon in general.

Other Post

Inspirasi Dari Kemenangan Daud Atas Jalut

May 14, 2024

Energi Bersih Diantara Sampah dan Kotoran

May 14, 2024

Mesin-Mesin Peradaban

May 14, 2024

BioLPG, How Much Does It Cost?

May 14, 2024

Low Cost Sustainable Aviation Fuel (SAF)

May 14, 2024

Categories

Renewable Energy

Please register first!

For post a new comment. You need to login first. Login

Comments

No comments