Regenerative Energy: Materials, Energy and Financial Balances

Advanced Renewable

Tue , 23 Apr 2024 21:20 WIB

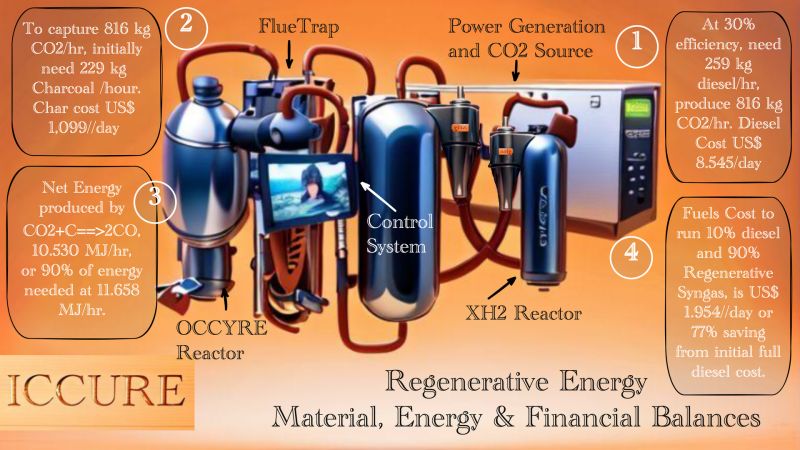

The most common detailed questions when we introduce the concept of Regenerative Energy (RE) are about material requirements, energy balance and the feasibility of this RE from a financial perspective. So the one slide below can explain everything at once.

The calculation model we use is a Diesel Power Plant (DPP) with a capacity of 1 MW. Assuming the efficiency of converting diesel energy to electricity is 30%, this plant requires 259 kg/hour of diesel fuel or around 6.2 tons of diesel/day, with the current industrial diesel price of US$ 1,374/ton fuel costs around US$ 8,545/day. However, in the RE concept, this DPP actually also has its own new energy source, namely from its CO2 emissions, which it emits around 816 kg/hour.

This CO2 can be converted into new energy by reacting it with charcoal or carbon. It takes 229 kg of charcoal to process 816 kg of CO2. In the RE concept, CO2 is reacted with C to become 2CO, and then burned back into energy plus more CO2, then there will be an accumulation of this CO2 under our control. This is what can be used as a source of energy in a sustainable manner.

It's just that you still need additional charcoal and 10% diesel because the compression engine requires ignition, which CO gas cannot provide unless the temperature is very high. So in its stable condition, DPP operations which were originally 100% diesel, and required 6.2 tons of diesel/day, now require 620 kg of diesel/day and 5.5 tons of charcoal per day. However, the price of this charcoal is much lower than diesel and easily available, only around US$ 200/ton.

So the total fuel cost to produce the same energy is only US$ 1,954/day. This means that by utilizing CO2 and charcoal, fuel costs for this 1 MW DPP can be reduced by 77% compared to using diesel entirely.

For this of course investment is needed, namely reactors that enable the entire series of conversions from CO2 to syngas which is worthy of replacing up to 90% of diesel fuel, or what we call S90! By rough calculation, our team is ready to build the entire reactors configuration at a cost equivalent to 10 months of fuel cost savings mentioned above.

There are other income opportunities with this RE concept, namely carbon credits. When the price of carbon credits increases towards 2030, the income from these carbon credits could be very significant in reducing the operating costs of carbon-free plants such as using this RE technology. Being clean and green doesn't have to be expensive, it can even be a cost cutting leadership center!

Other Post

Bali Net Zero (BNZ) Project

Apr 23, 2024

Low Cost Carbon Capture (LC3)

Apr 23, 2024

Potensi Di Balik Hukum Kekekalan Energi

Apr 23, 2024

Categories

Renewable Energy

Please register first!

For post a new comment. You need to login first. Login

Comments

No comments